Get Lost Wax Precision Casting Parts From China Manufacturers and Suppliers.

Lost wax precision casting is a manufacturing process that involves creating a mold from a wax pattern, which is then filled with molten metal to create a final product.

This process is known for its ability to produce parts with high accuracy and intricate details, making it a popular choice in industries such as aerospace, automotive, and medical.

China has become a leading manufacturer of lost wax precision casting parts, with many companies specializing in this process.

These manufacturers offer a wide range of products, from small components to large, complex parts. They also provide a variety of materials, including stainless steel, carbon steel, and aluminum, to meet the needs of different industries.

Lost Wax Precision Casting Parts Manufacturer China: Top Companies to Consider for Your Business Needs

Finding a reliable lost wax precision casting parts manufacturer in China can be a challenge, given the large number of companies offering this service.

However, by doing thorough research and choosing a reputable manufacturer with a proven track record, businesses can benefit from high-quality parts at competitive prices.

Understanding Lost Wax Precision Casting

Lost wax precision casting is a manufacturing process that has been around for centuries.

It is a process used to create intricate and detailed metal parts with high precision and accuracy.

This process is commonly used in the production of metal parts for various industries, including aerospace, automotive, and medical.

The lost wax precision casting process involves several steps.

First, a wax pattern is created from a mold or a 3D model. The wax pattern is then coated with a ceramic shell to create a mold.

The mold is heated, and the wax is melted out, leaving a cavity in the ceramic shell.

Next, molten metal is poured into the ceramic shell, filling the cavity left by the wax.

The metal is left to cool and solidify before the ceramic shell is broken away, revealing the final metal part.

The final metal part is then cleaned and finished to the desired specifications.

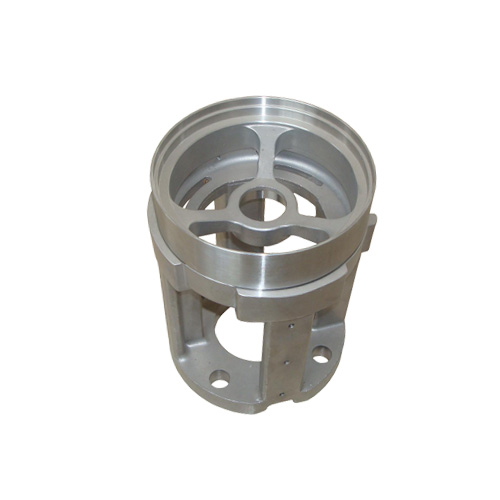

This process allows for the creation of highly detailed and complex metal parts with tight tolerances.

It is also a cost-effective method for producing small to medium-sized production runs of metal parts.

Lost wax precision casting has several advantages over other manufacturing processes.

It allows for the creation of intricate and complex metal parts with high precision and accuracy.

It also allows for the production of metal parts with thin walls and complex geometries that are difficult or impossible to produce with other methods.

Overall, lost wax precision casting is a versatile and cost-effective method for producing high-quality metal parts with intricate designs and tight tolerances.

Top Manufacturers in China

China is home to many manufacturers of lost wax precision casting parts. Here are some of the top manufacturers in the country:

- Dongying Hengke Precision Metal Co., Ltd.

- Ningbo Yinzhou Fuchun Precision Casting Co., Ltd.

- Qingdao Tianluping Metal Products Co., Ltd.

- Zhejiang Fantian Foundry & Trading Co., Ltd.

- Ningbo Tongda Precision Casting Co., Ltd.

Dongying Yicheng Precision Metal Co., Ltd. is a leading manufacturer of lost wax precision casting parts in China.

They specialize in producing high-quality parts for a variety of industries, including automotive, aerospace, and medical. Their team of experienced engineers and technicians ensures that each part is made to exact specifications.

Ningbo Yinzhou Fuchun Precision Casting Co., Ltd. has been in the business of precision casting for over 20 years. They have a wide range of capabilities, including investment casting, sand casting, and die casting. They have a reputation for producing high-quality parts at competitive prices.

Qingdao Tianluping Metal Products Co., Ltd. is a manufacturer of precision casting parts for the automotive, marine, and construction industries. They have a state-of-the-art facility and a team of skilled workers who are dedicated to producing high-quality parts.

Zhejiang Fantian Foundry & Trading Co., Ltd. is a manufacturer of lost wax precision casting parts for the aerospace, automotive, and medical industries. They have a strong focus on quality and customer service, and they are committed to delivering parts that meet or exceed their customers’ expectations.

Ningbo Tongda Precision Casting Co., Ltd. has been in the business of precision casting for over 30 years. They have a wide range of capabilities, including investment casting, sand casting, and die casting. They have a reputation for producing high-quality parts at competitive prices.

Manufacturing Process

Lost wax precision casting is a complex process that involves several steps to create high-quality parts.

The process begins with the creation of a wax model, which is used to create a mold.

The mold is then filled with molten metal, which solidifies and takes the shape of the mold.

Finally, the mold is broken, and the finished part is removed.

The following steps are involved in the manufacturing process of lost wax precision casting parts:

- Wax Pattern Creation: The first step involves creating a wax pattern of the desired part. This is done using a wax injection molding machine, which injects molten wax into a mold to create the pattern. The pattern is then removed from the mold and inspected for defects.

- Assembly: Once the wax pattern is created, it is assembled with other wax components to create a complete assembly. This assembly is then attached to a wax sprue, which is used to create a channel for the molten metal to flow into the mold.

- Shell Building: The wax assembly is then coated with a ceramic shell to create a mold. This shell is created by repeatedly dipping the wax assembly into a ceramic slurry and then coating it with a fine ceramic sand. This process is repeated several times until a thick shell is formed.

- Burnout: Once the ceramic shell is complete, it is placed in a furnace and heated to a high temperature to melt and remove the wax. This leaves behind a hollow ceramic mold.

- Casting: The ceramic mold is then filled with molten metal, which is poured into the mold through the sprue. The metal solidifies and takes the shape of the mold.

- Finishing: Once the metal has cooled and solidified, the ceramic shell is broken away, and the part is removed. The part is then cleaned and finished to remove any excess material and achieve the desired surface finish.

Overall, the lost wax precision casting process is a highly precise and intricate method of manufacturing parts.

It requires skilled technicians and specialized equipment to create high-quality parts that meet the exact specifications of the customer.

Quality Control Measures

Lost wax precision casting is a highly technical process that requires strict quality control measures.

To ensure that the final product meets the required standards, manufacturers in China implement various quality control measures throughout the production process.

One of the primary quality control measures is the use of advanced testing equipment.

Manufacturers in China use state-of-the-art equipment to test the metal composition, mechanical properties, and dimensional accuracy of the castings.

This helps to ensure that the final product meets the required specifications and tolerances.

In addition to testing equipment, manufacturers also implement strict process control measures.

They closely monitor the entire production process, from wax injection to heat treatment, to ensure that each step is carried out correctly.

This helps to minimize defects and ensure consistent quality.

To further ensure quality, manufacturers in China also conduct rigorous inspections of the finished products.

They use various inspection techniques, such as visual inspection, X-ray inspection, and dye penetration testing, to detect any defects or imperfections in the castings.

Finally, manufacturers in China implement a comprehensive quality management system.

This system covers all aspects of the production process, from design and development to delivery and after-sales service.

It helps to ensure that the quality of the castings is consistently high and that any issues are promptly addressed.

Overall, the combination of advanced testing equipment, strict process control measures, rigorous inspections, and a comprehensive quality management system helps Chinese manufacturers to produce high-quality lost wax precision casting parts.

Common Challenges and Solutions

Lost wax precision casting is a complex process that involves several stages and requires high precision and attention to detail.

Despite the advanced technology and equipment used in the process, there are still some common challenges that manufacturers face.

Here are some of the challenges and solutions to overcome them:

1. Porosity

One of the most common challenges in lost wax precision casting is porosity. Porosity is the presence of small holes or voids in the casting, which can affect the strength and durability of the part. To prevent porosity, manufacturers need to ensure that the wax pattern is properly cleaned and dried before it is coated with ceramic. They should also use high-quality ceramic materials and ensure that the coating is uniform and free of defects.

2. Shrinkage

Shrinkage is another challenge in lost wax precision casting. Shrinkage occurs when the molten metal cools and solidifies, causing the part to shrink and deform. To prevent shrinkage, manufacturers need to use the right alloy composition and ensure that the casting temperature and cooling rate are controlled properly. They should also use a gating system that allows for proper feeding and venting of the molten metal.

3. Surface Finish

Surface finish is an important aspect of lost wax precision casting, as it affects the appearance and functionality of the part. Achieving a smooth and uniform surface finish can be challenging, especially for complex parts with intricate details. To improve surface finish, manufacturers can use different techniques such as sandblasting, polishing, and electroplating. They should also ensure that the mold is properly cleaned and prepared before casting.

In conclusion, lost wax precision casting is a complex process that requires high precision and attention to detail. Manufacturers face several challenges, including porosity, shrinkage, and surface finish. However, by using the right techniques and equipment, these challenges can be overcome, resulting in high-quality parts that meet the customer’s requirements.

Applications of Lost Wax Precision Casting Parts

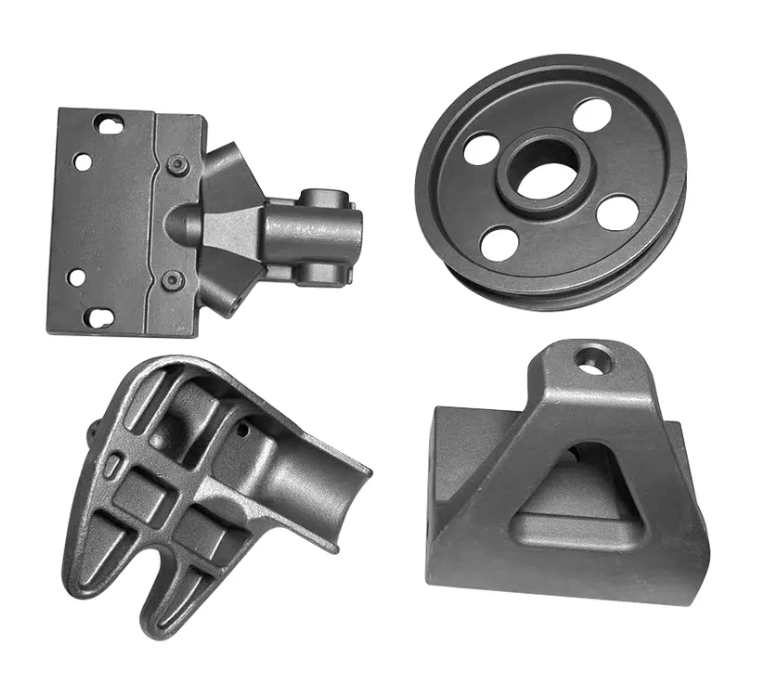

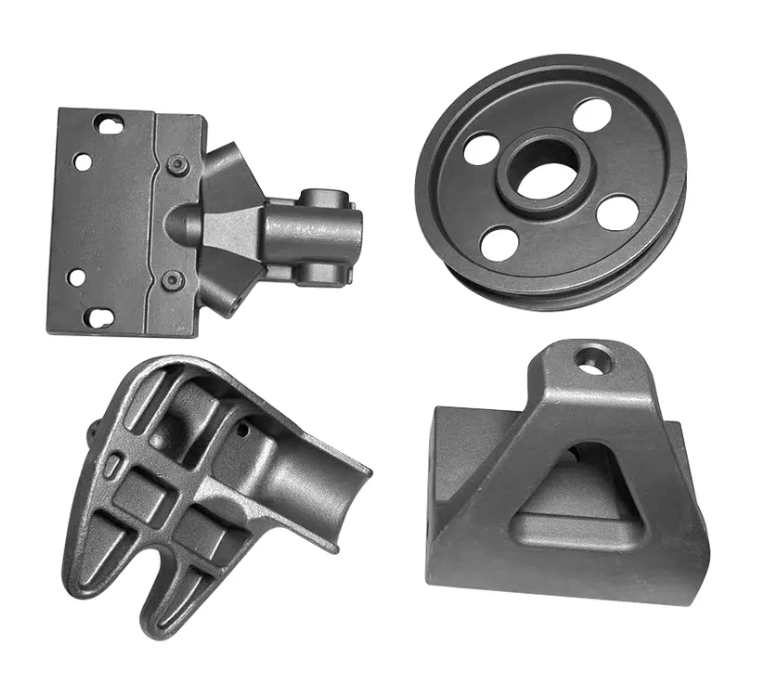

Lost wax precision casting parts have a wide range of applications in various industries.

The precision and accuracy of these parts make them ideal for use in critical applications where high-quality components are required.

Here are some of the common applications of lost wax precision casting parts:

Aerospace Industry

The aerospace industry is one of the biggest users of lost wax precision casting parts. These parts are used in aircraft engines, landing gears, and other critical components. The precision and accuracy of these parts are essential for ensuring the safety and reliability of aircraft.

Automotive Industry

Lost wax precision casting parts are widely used in the automotive industry for making engine components, transmission parts, and other critical components. The use of these parts helps to improve the performance and efficiency of vehicles while reducing their weight.

Medical Industry

The medical industry also uses lost wax precision casting parts for making various components such as implants, surgical instruments, and other medical devices. The precision and accuracy of these parts are crucial for ensuring the safety and effectiveness of medical procedures.

Marine Industry

The marine industry uses lost wax precision casting parts for making various components such as propellers, shafts, and other critical parts. The use of these parts helps to improve the performance and efficiency of marine vessels while reducing their weight.

Other Industries

Lost wax precision casting parts are also used in other industries such as the defense industry, power generation industry, and industrial machinery industry. These parts are used for making various critical components that require high precision and accuracy.

In conclusion, lost wax precision casting parts have a wide range of applications in various industries. The precision and accuracy of these parts make them ideal for use in critical applications where high-quality components are required.

Future Outlook

The future outlook for Lost Wax Precision Casting Parts Manufacturer China is promising. With the increasing demand for high-quality and complex precision parts in various industries, the company is well-positioned to meet the needs of its customers.

One of the key factors that will drive the growth of the company is its commitment to innovation and technology. Lost Wax Precision Casting Parts Manufacturer China has invested heavily in research and development to improve its manufacturing processes and product quality. This has resulted in the production of parts that are not only precise but also more durable and cost-effective.

Another factor that will contribute to the future success of the company is its focus on customer satisfaction. Lost Wax Precision Casting Parts Manufacturer China understands the importance of building long-term relationships with its customers and providing them with the highest level of service. By listening to their needs and feedback, the company can continuously improve its products and services to meet their evolving requirements.

Furthermore, Lost Wax Precision Casting Parts Manufacturer China has a strong presence in both domestic and international markets. With its extensive network of distributors and partners, the company can reach customers in various regions and industries. This diversification of its customer base helps to mitigate risks and ensure a stable revenue stream.

Overall, Lost Wax Precision Casting Parts Manufacturer China is well-positioned to capitalize on the growing demand for precision parts in various industries. With its focus on innovation, customer satisfaction, and market diversification, the company is poised for continued success in the years to come.

If you are looking for lost wax casting suppliers in China, you are in the right spot. We are a very professional supplier of lost wax casting equipment,

We supply our Lost Wax Casting overseas: Egypt, Turkey, Viet Nam, Philippines, Brazil, Pakistan, India, and Mexico. Our showroom locations: Egypt, Italy, France, Germany, Philippines, Peru, Indonesia, and Pakistan.