Investment Casting Buying Guide

Investment casting, also known as the lost wax process, is a manufacturing technique that involves the creation of complex parts through an injection molding process.

Initially, a wax pattern is coated with a refractory ceramic material, which hardens to form the internal geometry of the desired casting.

The wax is then melted out, creating a cavity that is filled with molten metal. After solidification, the metal casting is removed from the ceramic mold.

This process, with its origins dating back over 5500 years to ancient Egypt and China, finds applications in various industries, including dental fixtures, gears, jewelry, turbine blades, and machinery components.

The investment casting process begins with the fabrication of a wax pattern, which can also be made from plastic but is commonly made from reusable wax due to its easy removal.

As the pattern is destroyed during the process, a new pattern is required for each casting.

When producing parts in large quantities, a mold is used to manufacture the patterns. Similar to the molds used in expanded polystyrene casting, these molds for wax patterns can be cast or machined.

The careful calculation is necessary to determine the size of the master die, taking into account the shrinkage of wax, the ceramic material, and the metal casting, which can lead to some trial and error and increased costs.

The advantage of investment casting lies in its ability to manufacture castings with intricate and complex geometries since the mold does not need to be opened.

Multiple wax patterns can be combined or connected to a central sprue, forming a tree-like arrangement.

The patterns are then coated with a refractory slurry composed of fine-grained silica, water, and binders.

The ceramic layer is built up by repeated dipping or pouring over the pattern.

Once the ceramic coating is sufficiently thick, it is dried and hardened.

The next crucial step involves heating the mold to a specific temperature, causing the wax to melt and flow out, leaving behind the cavity for the metal casting.

The ceramic mold is further heated to strengthen it, remove any remaining wax or impurities, and drive out moisture.

The hot mold enables smooth flow of the molten metal, ensuring detailed and accurate castings. After pouring, the casting solidifies within the mold.

Finally, the ceramic mold is broken, and the parts are separated from the tree.

Investment casting offers several advantages, including the ability to produce complex parts with excellent surface finish, thin sections as narrow as .015 inches (.4mm), and high dimensional accuracy with tolerances as low as .003 inches (.076mm). It can accommodate a wide range of metals and alloys, even those difficult to machine or fabricate.

The process allows for automation in certain stages, but it is considered relatively expensive and complex.

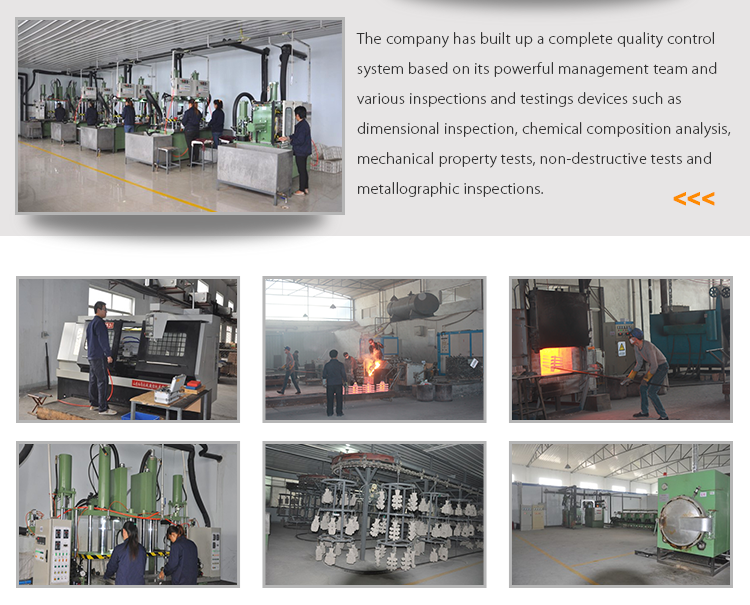

At Hengke Casting, we provide investment casting services tailored to your needs.

With our experience, facilities, and cost-effective tooling, we deliver accurately cast and economically viable products.

Our investment casting services offer benefits such as the ability to produce parts with intricate internal configurations, efficient production of small and intricate shapes, enhanced quality and consistency, consolidation of multiple machined parts, suitability for both long and short production runs, and the ability to manufacture parts not possible with traditional techniques. We work with a variety of materials, including steel, aluminum, stainless steel, brass, bronze, and copper.

Custom Investment Casting Foundry China: High-Quality Manufacturing Solutions

Custom investment casting is a widely used manufacturing process that allows for the creation of complex metal parts with high precision and accuracy.

Investment casting is a process that involves creating a wax model of the desired part, coating it in ceramic, and then melting the wax away to create a mold.

Molten metal is then poured into the mold, creating the final part.

China is one of the leading countries in custom investment casting, with numerous foundries specializing in the process.

These foundries offer a range of services, from design and prototyping to casting and finishing.

With their expertise and advanced technology, Chinese investment casting foundries are able to produce high-quality parts for a variety of industries, including aerospace, automotive, and medical.

Custom Investment Casting Foundry: An Overview

Custom investment casting foundries in China are known for their ability to produce high-quality metal parts with intricate designs and complex geometries.

Investment casting, also known as lost-wax casting, is a manufacturing process that involves creating a wax pattern, coating it with a ceramic shell, and then melting the wax out to create a hollow cavity.

Molten metal is then poured into the cavity, creating a solid metal part that is an exact replica of the wax pattern.

Custom investment casting foundries in China have the expertise and equipment to produce a wide range of metal parts, including those made from stainless steel, carbon steel, aluminum, brass, and bronze.

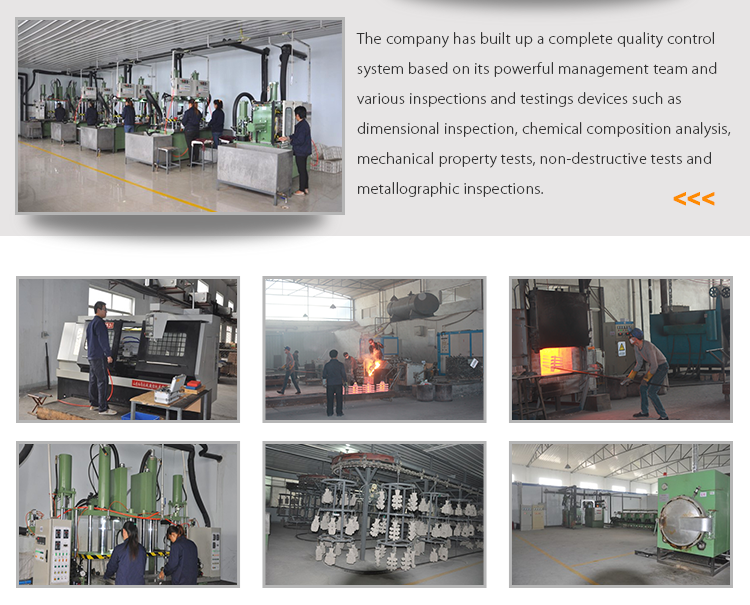

These foundries use advanced technology and equipment to ensure that their products meet the highest quality standards.

One of the advantages of custom investment casting is that it allows for the production of parts with complex geometries and intricate designs that would be difficult or impossible to produce using other manufacturing processes.

This makes investment casting an ideal choice for a wide range of applications, including aerospace, automotive, medical, and industrial.

In addition to producing high-quality metal parts, custom investment casting foundries in China also offer a range of value-added services, such as machining, heat treatment, and surface finishing.

These services help to ensure that the final product meets the customer’s exact specifications and requirements.

Overall, custom investment casting foundries in China play a critical role in the manufacturing industry, providing high-quality metal parts that are essential for a wide range of applications.

With their expertise and advanced technology, these foundries are well-positioned to meet the growing demand for custom metal parts in today’s global marketplace.

The Investment Casting Process

Investment casting, also known as lost-wax casting, is a manufacturing process used to create complex and intricate metal parts.

This process involves creating a wax pattern of the desired part, coating it with a ceramic material, and then melting the wax away to create a mold. Molten metal is then poured into the mold, filling the space left by the wax pattern.

Once the metal has solidified, the ceramic shell is broken away to reveal the finished part.

The investment casting process offers many advantages over other manufacturing techniques.

One of the biggest advantages is the ability to create complex and intricate parts with high accuracy and detail.

This process also allows for a wide range of materials to be used, including steel, aluminum, bronze, and more.

The investment casting process can be broken down into several steps:

- Wax pattern creation: A wax pattern of the desired part is created using a mold or 3D printing technology.

- Wax assembly: The wax patterns are attached to a wax sprue, which is a central wax rod that will be used to create a mold.

- Ceramic shell creation: The wax assembly is coated with a ceramic material to create a shell around the wax patterns.

- Wax removal: The ceramic shell is heated to melt and remove the wax patterns, leaving a cavity in the shape of the desired part.

- Pouring: Molten metal is poured into the ceramic shell cavity.

- Cooling: The metal is allowed to cool and solidify.

- Shell removal: The ceramic shell is broken away, revealing the finished metal part.

Overall, the investment casting process is a versatile and precise manufacturing technique that allows for the creation of complex and detailed metal parts.

The Role of China in the Investment Casting Industry

China plays a significant role in the global investment casting industry. As the world’s largest manufacturer and exporter of investment castings, China has become a leading player in the industry.

Chinese investment casting foundries are known for their high-quality products, competitive pricing, and fast turnaround times.

The country’s investment casting industry has been growing rapidly in recent years, thanks to advancements in technology and an increasing demand for precision casting products.

One of the reasons why China has become a prominent player in the investment casting industry is its vast network of foundries.

These foundries are spread across the country, with many located in the coastal regions. This strategic location gives them easy access to transportation hubs, making it easier to ship products to customers worldwide.

Another factor that has contributed to China’s success in the investment casting industry is the country’s focus on research and development.

Chinese foundries invest heavily in technology and innovation, which allows them to produce high-quality products that meet the needs of customers around the world.

China’s investment casting industry also benefits from the country’s large pool of skilled labor.

There are many highly trained and experienced workers in China who are capable of producing complex investment castings to precise specifications.

In conclusion, China’s investment casting industry has become a major player in the global market thanks to its vast network of foundries, focus on research and development, and skilled labor force.

As the industry continues to grow, it is likely that China will remain a key player in the investment casting industry for many years to come.

Key Players in China’s Investment Casting Foundry

China’s investment casting foundry industry is highly competitive, with a large number of key players in the market.

These companies are known for their high-quality products, advanced technology, and excellent customer service.

Here are some of the leading investment casting foundries in China:

1. Dongying Hengke Precision Metal Co., Ltd.

Dongying Hengke Precision Metal Co., Ltd. is a leading investment casting foundry in China.

The company specializes in the production of high-quality precision castings, including carbon steel, alloy steel, stainless steel, and other materials.

They have advanced production equipment, including wax injection machines, shell-making machines, and heat treatment equipment.

2. Ningbo Sylue Machine Co., Ltd.

Ningbo Sylue Machine Co., Ltd. is another top investment casting foundry in China. The company has a wide range of products, including precision castings, sand castings, and die castings. They also offer CNC machining services and surface treatment services. Ningbo Sylue Machine Co., Ltd. has a strong focus on quality control, and they have a team of experienced engineers and technicians who ensure that each product meets the highest standards.

3. Shandong Jingyanggang Metal Equipment Co., Ltd.

Shandong Jingyanggang Metal Equipment Co., Ltd. is a leading investment casting foundry in China that specializes in the production of stainless steel castings. The company has advanced production equipment and a team of skilled technicians who ensure that each product meets the highest quality standards. Shandong Jingyanggang Metal Equipment Co., Ltd. has a strong focus on customer service, and they work closely with their clients to ensure that their needs are met.

4. Zhejiang Dongrun Casting Industry Co., Ltd.

Zhejiang Dongrun Casting Industry Co., Ltd. is a well-known investment casting foundry in China that specializes in the production of aluminum and zinc die castings. The company has advanced production equipment and a team of skilled technicians who ensure that each product meets the highest standards. Zhejiang Dongrun Casting Industry Co., Ltd. has a strong focus on innovation, and they are constantly developing new products and technologies to meet the changing needs of their customers.

These are just a few of the key players in China’s investment casting foundry industry. Each of these companies has a strong reputation for quality, innovation, and customer service, and they are well-positioned to meet the growing demand for investment castings in China and around the world.

Benefits of Choosing Chinese Investment Casting Foundry

Chinese investment casting foundries have become increasingly popular in recent years due to their ability to deliver high-quality products at a lower cost than their Western counterparts. Here are some benefits of choosing a Chinese investment casting foundry for your next project:

1. Cost Savings

One of the most significant benefits of choosing a Chinese investment casting foundry is the cost savings. Chinese foundries typically have lower labor and overhead costs, which allows them to offer their services at a lower price point. This makes them an attractive option for companies looking to reduce their manufacturing costs without sacrificing quality.

2. Wide Range of Materials

Chinese investment casting foundries offer a wide range of materials, including stainless steel, carbon steel, aluminum, and more. This allows companies to choose the material that best suits their needs and budget.

3. High-Quality Products

Despite the lower cost, Chinese investment casting foundries are known for producing high-quality products. They use advanced technology and machinery, and their workers are highly skilled and experienced. Additionally, many Chinese foundries have certifications such as ISO 9001, which ensures that they meet international quality standards.

4. Efficient Turnaround Time

Chinese investment casting foundries are known for their efficient turnaround times. They have streamlined production processes and can deliver products quickly without sacrificing quality. This is especially important for companies with tight deadlines or those looking to get their products to market as quickly as possible.

In summary, choosing a Chinese investment casting foundry can offer significant cost savings, a wide range of materials, high-quality products, and efficient turnaround times. These benefits make Chinese foundries an attractive option for companies looking to reduce their manufacturing costs without sacrificing quality.

Challenges in China’s Investment Casting Foundry

China’s investment casting foundries have been facing a range of challenges in recent years. These challenges include:

1. Quality Control Issues

One of the primary challenges in China’s investment casting foundry is maintaining consistent quality control. The quality of the castings produced is critical to the success of the products they are used in, and any defects or variations can lead to significant problems down the line. To address this challenge, foundries need to invest in advanced testing and inspection methods to ensure that every casting meets the required standards.

2. Environmental Regulations

China has been tightening its environmental regulations in recent years, which has had a significant impact on investment casting foundries. These regulations have placed strict limits on emissions and waste disposal, which has led to increased costs and operational challenges for many foundries. To comply with these regulations, foundries need to invest in advanced equipment and processes to reduce their environmental impact.

3. Labor Costs

Labor costs have been rising in China in recent years, which has made it more difficult for investment casting foundries to remain competitive. Foundries need to invest in automation and other technologies to reduce their reliance on manual labor and increase efficiency.

4. Intellectual Property Theft

Intellectual property theft is a significant concern in China’s investment casting industry. Many foundries have been accused of stealing designs and other proprietary information from their customers, which can lead to legal disputes and damage to the reputation of the foundry. To address this challenge, foundries need to implement strict security measures and enforce strict intellectual property policies.

In conclusion, China’s investment casting foundries face a range of challenges that require significant investment and effort to overcome. By addressing these challenges head-on, foundries can improve their operations, increase efficiency, and remain competitive in the global market.

Future Trends in China’s Investment Casting Foundry

China’s investment casting industry has experienced significant growth over the past few years and is expected to continue expanding in the future. Here are some trends that are likely to shape the industry in the coming years:

1. Automation and Digitalization

As with many industries, automation and digitalization are becoming increasingly important in investment casting. China’s foundries are investing in advanced equipment and software to improve production efficiency and quality. This includes the use of 3D printing, robotics, and machine learning to optimize the casting process.

2. Environmental Sustainability

Environmental sustainability is a growing concern for many industries, including investment casting. China’s foundries are taking steps to reduce their environmental impact by implementing cleaner production processes and using more environmentally friendly materials. This includes the use of recyclable materials and reducing energy consumption.

3. Increased Collaboration

Collaboration between foundries and their customers is becoming more important in the investment casting industry. This includes early involvement in the design process, prototyping, and testing to ensure the final product meets the customer’s requirements. China’s foundries are working closely with their customers to provide customized solutions that meet their needs.

4. Globalization

China’s investment casting industry is becoming increasingly globalized, with many foundries exporting their products to countries around the world. This trend is expected to continue as China’s foundries continue to improve their production capabilities and quality standards.

In conclusion, China’s investment casting industry is poised for continued growth in the coming years, driven by advances in technology, environmental sustainability, increased collaboration, and globalization.

Conclusion

In conclusion, Custom investment casting Foundry China offers a reliable and cost-effective solution for producing high-quality metal parts.

With its advanced technology and skilled workforce, the foundry is capable of producing complex and intricate parts with tight tolerances and superior surface finishes.

One of the main advantages of custom investment casting is its versatility. It can be used to produce parts of various sizes and shapes, from small and intricate components to large and complex structures.

This makes it an ideal choice for a wide range of industries, including aerospace, automotive, medical, and more.

Another advantage of custom investment casting is its ability to produce parts with exceptional accuracy and consistency.

This is due to the use of high-quality molds and advanced manufacturing techniques, which ensure that each part is produced to the exact specifications of the customer.

Overall, Custom investment casting Foundry China is a reliable and cost-effective solution for producing high-quality metal parts.

Its advanced technology, skilled workforce, and commitment to quality make it an ideal partner for businesses looking to streamline their production processes and improve their bottom line.