Importing Steel Castings from China to the USA – A Guide

Introduction

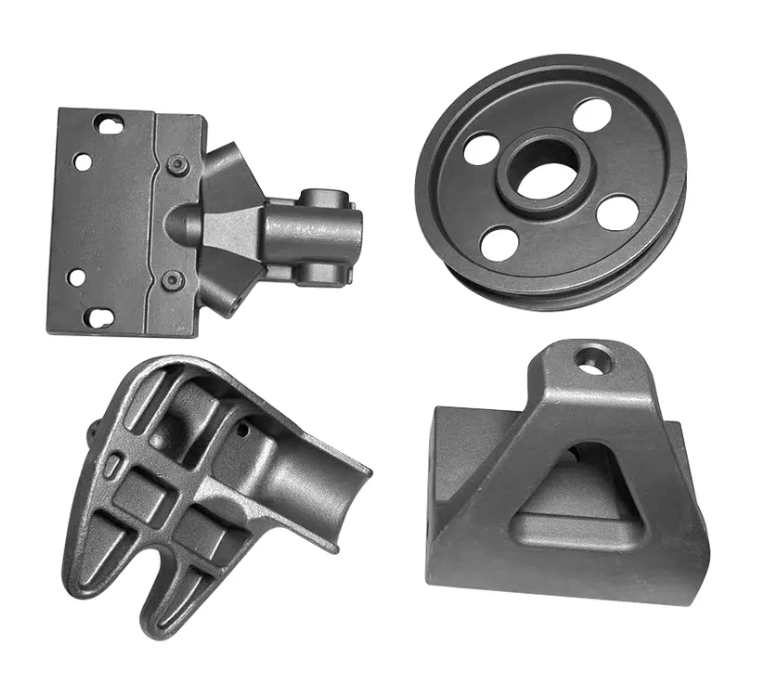

Steel castings form crucial components in heavy machinery, infrastructure, defense equipment, and numerous industrial applications. They provide the high strength, durability, and custom geometries needed in harsh, demanding environments.

In the past few decades, China has emerged as a major global supplier of steel castings to markets like the USA due to its cost competitiveness, vast production capacity, and improving quality standards. This article provides a comprehensive guide on importing Chinese steel castings into the USA covering key factors like sourcing, logistics, regulations, risks, and the future outlook.

Overview of the Chinese Steel Castings Industry

China dominates the global steel castings market, producing over 50% of the world’s castings. Key facts about the industry include:

- Annual production capacity stands at around 35 million metric tons, with revenue exceeding USD $75 billion. Over 7000 foundries of varying sizes exist.

- Main production hubs are in eastern provinces like Zhejiang, Jiangsu, Shanghai and Shandong. but western China is also developing capabilities.

- Casting methods include green sand, resin sand, investment, lost foam and low pressure casting. Automation levels are rising.

- Major end-user sectors include construction/infrastructure, mining, oil/gas, power, railways, wind power, heavy engineering, etc.

- Quality standards are improving with China’s Manufacturing 2025 initiative. More foundries are getting ISO certified.

- Major players are Zoomlion, Hitachi, CITIC, Riyue Heavy Industry and Wuhan Iron & Steel. Many small/medium foundries also exist.

This vast capacity and cost competitiveness make China an attractive option for sourcing steel castings. Understanding the market dynamics is vital for global buyers.

Sourcing Considerations

When sourcing steel castings from China, key factors for importers include:

- Specifications: Clearly specify the technical requirements – materials, dimensions, tolerances, testing/inspection protocols, surface finish, cast design, etc. Review samples before production.

- Capabilities: Assess foundries’ capabilities in the needed casting process (sand, investment, etc), metals/alloys used, machining, and quality systems. Get plant audits done if possible.

- Capacity: Evaluate production capacity and workload of the foundry to ensure timely supply. Seek committed delivery schedules.

- Pricing: Get price quotations from multiple foundries. Negotiate based on order volumes, customization needs and production costs. Calculate total landed costs.

- Certifications: Review foundries’ certifications like ISO 9001. Aerospace/defense foundries need additional AS/EN certifications. Verify certification validity.

- Contracts: Have detailed contracts covering commercial terms, quality clauses, compliance documentation, inspection rights, delivery timelines and penalties for non-compliance.

Thorough due diligence during supplier selection is vital to get the quality, reliability and pricing needed from Chinese foundries. Visiting the foundry beforehand significantly reduces risk.

Logistics and Shipping

Coordinating shipping and logistics from China needs careful planning considering the distance and complexity. Key aspects to address include:

- Packing: Castings require sturdy wooden crating with sufficient padding to prevent any damage during transit. Ensure pack sizes align with container dimensions.

- Loading: Cargo needs to be securely loaded into containers at the factory with proper stacking, bracing, and lashing. Lock containers to prevent theft.

- Documents: Relevant export documents need to be prepared by the supplier – bill of lading, certificate of origin, packing lists, inspection certificate, customs declaration, etc.

- Transport mode: Sea freight is most economical for large volumes of steel castings. Air freight can expedite urgent deliveries. Evaluate lead times.

- Customs clearance: Hire an experienced freight forwarder to handle US customs clearance efficiently. Provide them necessary information beforehand to avoid delays.

- Insurance: Marine insurance needs to be purchased covering risks like damage/loss during transit. Assess policy terms like settlement time, disputes resolution, etc.

- Payment terms: Use payment methods like LC, CAD or pay part advance and the remainder post-delivery. This reduces non-performance risks.

Well-coordinated logistics and prudent payment structures help import cost-effective yet reliable supplies of castings from China.

US Customs Regulations

When importing Chinese steel castings, key US customs regulations include:

- Duty rates: Imported steel castings face duties of up to 10.5%. This is based on the harmonized tariff code of the specific component. Consulting a customs broker is advisable.

- Country of Origin: The product must be sufficiently transformed in China to qualify as made in China, or duties can be higher. Castings cannot be just minimally processed there.

- Valuation: Customs value declaration must follow transaction valuation based on price actually paid or payable. Any discounts or rebates must be declared.

- Antidumping duty: If the casting type is included in existing Commerce Dept anti-dumping orders, additional duties based on previous dumping margins could apply.

- Other compliance: USMCA, Buy American Act, product safety, hazardous material handling, intellectual property rules etc. apply for imported goods.

Knowing the relevant import regulations and dutiable costs allows effective landed cost calculation. Hiring experienced customs brokers also smoothens the import clearance process.

Risk Factors and Challenges

While Chinese castings offer cost benefits, the long supply chain also brings risks that importers must manage, including:

- Quality issues: Inferior raw materials, inadequate process controls and insufficient testing can cause product defects. Pre-shipment inspection and sample approvals are must.

- Delayed delivery: Lack of capacity juggling, production delays and port congestion can extend timelines. Keeping buffer inventory is suggested.

- Order confusion: Miscommunication on specifications due to language barriers or units of measurement errors can result in wrong castings being shipped.

- Unprofessional practices: Some Chinese foundries engage in unethical practices like unauthorized subcontracting, reusing returned defective castings, or not following standards.

- Intellectual property theft: Lack of IP protection in China poses risks of proprietary casting designs or trade secrets being stolen and replicated without consent.

- Geopolitical disruptions: Political tensions or trade disputes can suddenly halt cargo flows. Diversifying sourcing across multiple countries mitigates this risk.

Proper supplier vetting, contracts, and quality control safeguards during the procurement process are essential to avoid hassles during the importing process.

Future Outlook for the Trade

The future outlook for importing Chinese steel castings to the USA remains strong. Demand drivers include:

- Infrastructure renewal: Government initiatives like the bipartisan Infrastructure Law signal greater demand for heavy castings for construction equipment. This benefits Chinese suppliers.

- Reshoring by US manufacturers: As companies move production back to the US, they will rely on China for lower cost components like castings.

- Supply chain diversification: Importers are adopting “China + 1” strategies adding alternative locations. But China remains the primary volume source.

- Electric vehicles: EVs use large complex cast parts for motors and frames, playing to China’s castings strength.

- Lower Chinese labor costs: Even with some manufacturing automation, China still has major labor cost advantages that will persist.

However, global foundries are also upgrading capabilities, as US companies focus more on domestic or nearshore suppliers. Watching these evolving trends will be key.

Here are some key points about precision casting foundries in China:

- China is a major global hub for precision investment castings used in diverse industries including aerospace, automotive, medical, and more.

- Major production clusters exist in provinces like Zhejiang, Jiangsu, Shanghai, and Shandong. These benefit from access to skilled labor, supply chains, and transportation infrastructure.

- Leading Chinese precision casting foundries include CIREX, Longhua, Shanghai Pu Dong, YingYu, and Wuxi Degui. Many specialist foundries cater to specific industries.

- Chinese foundries utilize advanced precision casting processes like investment casting, vacuum casting, and lost wax casting to produce complex, high-tolerance metal parts.

- Typical materials cast include stainless steels, aluminum alloys, superalloys, and titanium. Foundries are highly experienced in these metals.

- Quality levels at top Chinese foundries now match global standards, with many having ISO, AS9100, Nadcap, and other certifications.

- Automation is increasing with robotic molding, 3D printing, and x-ray inspection incorporated into production lines.

- Costs are still 30-50% lower than Western foundries in most cases, making China competitive for global OEM sourcing.

- Concerns around quality control, counterfeits, and IP protection remain however, requiring buyer due diligence.

Chinese precision casting foundries offer a compelling value proposition but careful supplier screening is vital before sourcing finished castings or molds from China.

Conclusion

This guide covers the key factors involved in importing Chinese steel castings into the United States – from selecting the right foundries to navigating logistics, regulations, risks and growth opportunities. With diligent supplier management and oversight, Chinese castings can provide US manufacturers and infrastructure projects cost-effective components. However, prudent risk mitigation measures remain vital for smooth importing. As the global foundry landscape evolves, keeping adaptable sourcing strategies and maintaining alternatives will be advisable for sustained access to high-quality, affordable steel castings.

By Coco

By Coco