Best Investment Casting Manufacturers

Investment casting provides tremendous design flexibility, dimensional accuracy, and surface finish for producing intricate metal components across diverse industries.

Partnering with a quality investment casting manufacturer is key for gaining access to this specialized metal forming process.

This article explores leading global and domestic investment casting suppliers renowned for technical expertise, capacity, and manufacturing excellence.

Overview of the Investment Casting Process

Investment casting involves creating metal parts by pouring molten metal into a mold produced using a wax pattern of the part design.

It is valued for accuracy, versatility, and ability to form complex shapes.

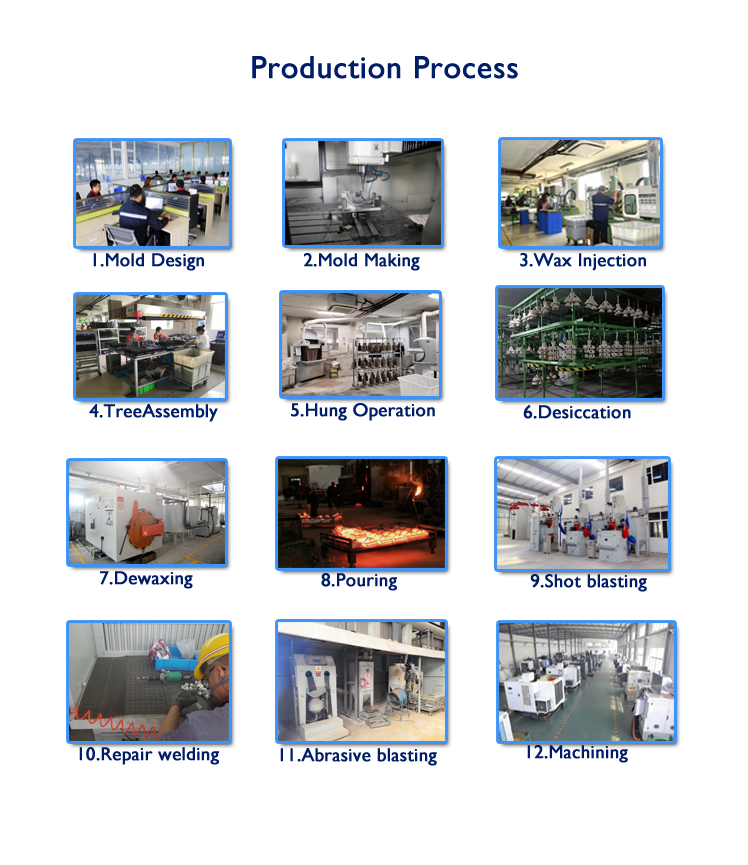

The key steps in the investment casting process are:

- Create a wax pattern of the part design

- Assemble patterns into a tree and coat with ceramic slurry

- De-wax to remove patterns leaving behind a ceramic mold

- Pour molten metal into the mold to form the casting

- Remove cast parts from the mold

- Cut off extra metal, clean and inspect finished parts

The dimensional accuracy and surface quality achieved drives applications in aerospace, military, medical, automotive, and industrial components manufacturing.

Benefits of Investment Casting

- Excellent surface finishes and fine details

- Tight dimensional tolerances

- Ability to produce complex geometries

- Consolidation of parts through integrated cast designs

- Casting of delicate and hollow components

- Wide range of castable metals like stainless steel, aluminum, cobalt, titanium, etc.

- Scalable process from prototypes to high-volume production

Leading Global Investment Casting Manufacturers

Hengke Metal

Hengke Metal offers aerospace-grade investment castings in exotic alloys and stainless steel from facilities in China. Capabilities include machining, finishing, and NDT testing.

Alcoa

Alcoa is a lightweight metals leader providing aluminum and titanium investment castings to aerospace and IGT customers worldwide. Services range from prototyping to high-volume production.

Doncasters Group

Doncasters utilizes precision investment casting to manufacture critical superalloy components for aerospace engines and airframes out of UK and US facilities.

MetalTek

Wisconsin-based MetalTek offers full-service investment castings in stainless steels, carbon steels, high alloys, and aluminum for diverse markets including military, mining, and medical.

Signicast Corporation

Significant is an acclaimed investment casting expert serving the medical, aerospace, defense, and industrial sectors from multiple US manufacturing plants.

Leading Investment Casting Companies in China

Dongying Hengke Precision Metal Co.,Ltd.

A premier investment casting manufacturer in China providing steel, aluminum, and superalloy castings for OEM automotive and aircraft components.

Ningbo Jiwei Investment Casting

Ningbo Jiwei offers stainless steel and carbon steel investment castings for pumps, valves, instrumentation, machine parts, and other applications.

Taizhou United Die Casting

Produces precision investment castings in aluminum, zinc, and magnesium alloys for telecom, medical, defense, automotive, and electronics industries.

Zhejiang Wanshun Investment Casting

Wanshun manufactures stainless steel and heat/corrosion-resistant alloy investment castings for oil and gas, chemical, and aerospace component needs.

Chongqing Kaijie Precision Casting

Kaijie provides small to medium-batch production of custom steel and iron investment castings for machinery and other specialized applications.

Key Considerations for Selecting a Manufacturer

Industry Experience

Look for extensive expertise in investment casting processes, tooling, finishing, and quality requirements for specific industries.

Alloys Handled

Manufacturers should have expertise in specialized alloys needed like stainless steel, Inconel, titanium, aluminum, etc.

Part Complexity

Ensure capabilities in delivering the design intricacy, tight tolerances, and surface finishes your components require.

Quality Systems

Stringent process controls and quality certifications (ISO, AS9100, etc.) reduce defects and validate capabilities.

R&D and Engineering

Design support, simulation analysis, rapid prototyping, and R&D for casting optimize manufacturability.

Secondary Processing

In-house heat treatment, machining, finishing, and inspection improve part quality and lead times.

Scalability

Manufacturers should have the capacity to support high-volume production along with lower-volume batches.

Leveraging Investment Casting Optimally

- Engage casting experts early in the design stage to improve manufacturability.

- Utilize rapid prototyping to accelerate iterations before committing to production tooling.

- Consolidate components into an integrated cast design to improve reliability.

- Specify heat treatments, finishes, and tolerances needed from the onset.

- Review casting samples from tooling closely before approving full production.

- Clarify responsibilities for the supply of consumable casting accessories and materials.

- Inspect and test cast parts thoroughly per an acceptance quality plan.

Conclusion

Investment casting enables the manufacturing of intricately detailed and high-precision metal parts out of various exotic and custom alloys when high performance is needed.

Partnering with a technically proficient and reliable casting supplier with extensive expertise and QC standards allows for harnessing maximum benefits from this specialized manufacturing process.

FAQs

Q: What is investment casting?

A: Investment casting involves creating metal parts by pouring molten metal into a ceramic mold produced using a wax pattern of the part design.

Q: What are the key steps in investment casting?

A: The main steps are creating a wax pattern, coating it with ceramic slurry, de-waxing to remove the pattern, pouring metal into the mold, removing the casting, and finishing.

Q: What are some benefits of investment casting?

A: Benefits include excellent surface finish, tight tolerances, ability to produce complex shapes, consolidated parts design, hollow and delicate castings, wide material choices, and scalable volumes.

Q: Who are some leading global investment casting companies?

A: Prominent global manufacturers include CIREX, Alcoa, Doncasters Group, MetalTek, and Signicast Corporation.

Q: Who are the major investment casting suppliers located in China?

A: Leading Chinese manufacturers include CIXI City Yuyuan, Ningbo Jiwei, Taizhou United Die Casting, Zhejiang Wanshun, and Chongqing Kaijie Precision Casting.

Q: What criteria matter most in selecting a casting supplier?

A: Critical considerations are industry experience, alloys handled, part complexity, quality systems, R&D and engineering support, secondary processing, and scalability.

Q: How can you leverage investment casting most effectively?

A: By involving casting experts early, using rapid prototyping, designing consolidated parts, specifying requirements upfront, reviewing samples before production, and thorough incoming inspection.

By Coco

By Coco